Selecting the right suppliers for sensors and PLC (Programmable Logic Controller) controls is crucial for the success of any industrial automation project. In India, where the automation industry is rapidly evolving, making an informed decision can be the difference between a system that operates seamlessly and one that is fraught with issues. Here are the top five considerations to keep in mind when choosing sensor and PLC control suppliers in India.

1. Technological Compatibility and Integration

When selecting sensor and PLC control suppliers in India, it’s essential to ensure that their products can seamlessly integrate with your existing systems. This means they should be compatible with the hardware and software you already use, avoiding the need for costly and time-consuming modifications. Suppliers should offer products that comply with open standards, facilitating interoperability and future scalability.

Consider the ease of integration with other automation components and the supplier’s ability to provide integration services. This can greatly reduce the complexity of system upgrades and expansions, ensuring a smooth transition and continuous operation.

2. Quality and Reliability

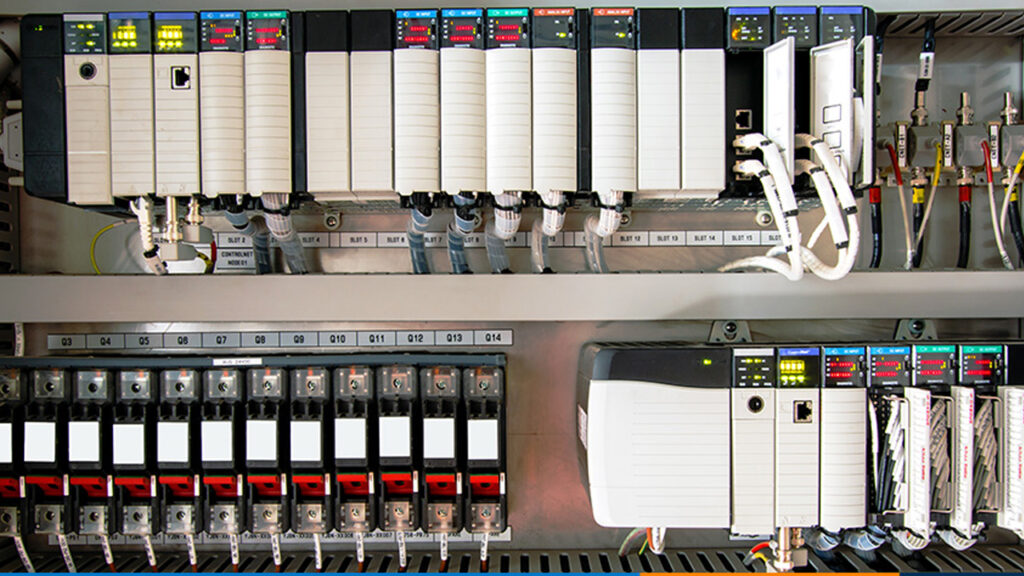

The sensors and PLC controls are the eyes and ears of your automation system; thus, their quality is paramount. High-quality components minimize the risk of failures that can lead to production halts and safety hazards. Reliable suppliers will have stringent quality control processes in place and provide warranties for their products.

It’s also wise to review the supplier’s history and reputation in the market. Longevity and a list of satisfied customers can be indicative of the reliability of their products. Remember, investing in quality upfront can save you from incurring higher costs in the long run due to equipment failure.

3. Technical Support and Service

A supplier’s commitment to customer service is revealed through their after-sales support. The availability of technical support can make a significant difference in operational continuity. Look for suppliers who offer comprehensive training programs, troubleshooting assistance, and maintenance services. A responsive support team can help you resolve issues quickly, reducing downtime.

Additionally, evaluate the supplier’s service network. A supplier with a widespread service network can provide faster on-site support, which is crucial for time-sensitive operations. Good technical support ensures that any problems are addressed promptly and efficiently, keeping your systems running smoothly.

4. Compliance and Certifications

Compliance with regulatory standards is non-negotiable. Suppliers should adhere to the relevant national and international standards, which serve as benchmarks for product safety and performance. Certifications like ISO and CE mark a supplier’s products as compliant with industry regulations and customer expectations. These certifications also reflect a supplier’s dedication to continuous improvement and quality management.

Furthermore, compliance ensures that you are not at risk of legal issues that can arise from using non-compliant products. Always verify the authenticity of the certifications and the accrediting bodies to ensure they are legitimate and recognized.

5. Cost-Effectiveness

While the initial purchase price is an important consideration, the total cost of ownership encompasses much more. This includes installation, operation, maintenance, and the potential for energy savings. A cost-effective supplier doesn’t just offer a competitive upfront price but also ensures that their products are durable and energy-efficient, leading to long-term savings.

Additionally, consider the supplier’s flexibility in pricing for bulk purchases or long-term contracts. A supplier that offers scalable solutions can accommodate your growth, providing more value for your investment. Ultimately, a cost-effective choice balances price with quality and service to provide the best return on investment.

Conclusion

In conclusion, selecting the right sensor and PLC control suppliers in India requires careful consideration of technological compatibility, quality, support services, compliance with standards, and cost-effectiveness. By taking these factors into account, businesses can ensure a successful and efficient automation system implementation. Remember to conduct thorough research, evaluate multiple suppliers, and choose one that aligns with your business goals and requirements.

I do not even know how I ended up here but I thought this post was great I dont know who you are but definitely youre going to a famous blogger if you arent already Cheers