In the evolving landscape of industrial technology, power connections play a pivotal role. The advent of Industry 4.0, growing infrastructure projects, and the need for reliable electrical connections have fueled the demand for innovative industrial plugs and sockets. Let’s delve into the latest trends and advancements in this critical field.

1. Rise of Smart and IoT-Enabled Plugs and Sockets

The new generation of industrial plugs and sockets integrates intelligent monitoring systems. Real-time monitoring of current, voltage, and temperature ensures efficient equipment maintenance and swift fault detection. Through mobile applications or remote control centers, users gain insights into equipment status, enhancing safety and productivity.

2. Emphasis on Safety and Compliance

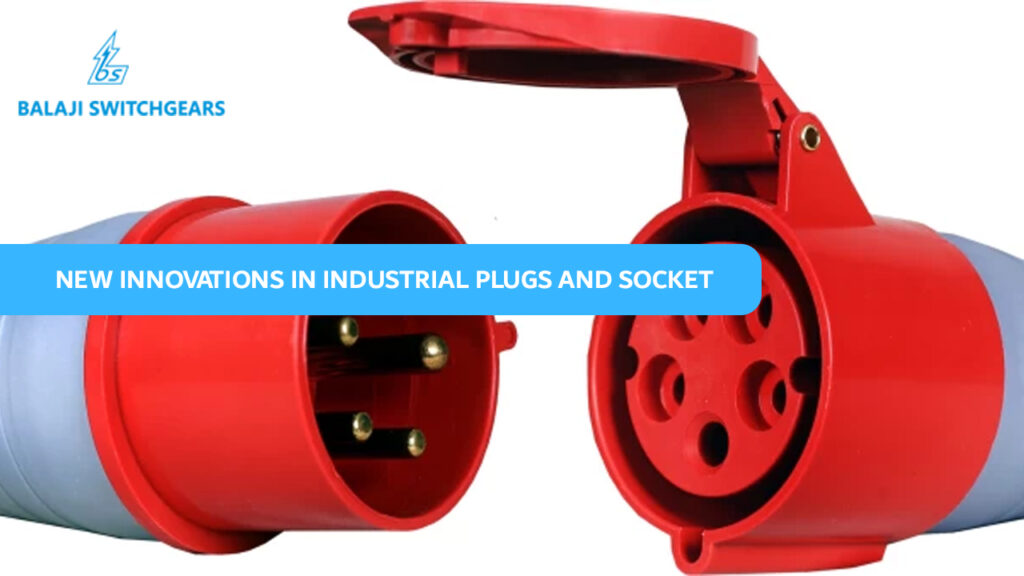

Safety remains paramount. These plugs and sockets are designed with rugged materials to withstand harsh environments. They meet the highest protection level standards, making them waterproof, dustproof, and impact-resistant. Whether in factory workshops or outdoor construction sites, they ensure reliable power connections without compromising safety.

3. Adoption of High-Performance Materials

Advanced materials are improving the durability and performance of industrial plugs and sockets. They can handle tough conditions and constant use without wearing out easily. With industries needing more power, these plugs and sockets are stepping up to provide high-capacity supply for today’s equipment. So, whether it’s handling higher currents or voltages, they’re ready to meet the demands of modern industrial settings, ensuring reliable power for all types of machinery and equipment.

4. Customization for Diverse Applications

Industrial plugs and sockets are used in different industries like manufacturing, construction, mining, energy, and logistics. They provide reliable power for big machines, heavy equipment, and automated production lines. These plugs and sockets can be customized to fit specific needs in different industries, making them easy to use in any setup. So, whether it’s powering machines in a factory or equipment at a construction site, these plugs and sockets are there to make sure everything runs smoothly.

5. Modularity and Interchangeability

Flexibility is key. Modular designs enable easy assembly and disassembly. Interchangeable components simplify maintenance and upgrades. As industrial processes evolve, these adaptable plugs and sockets keep pace, minimizing downtime.

6. Global Expansion and Market Penetration

The global industrial plug and socket market is on a steady growth trajectory. North America leads the way, with the United States dominating the market. China, too, experiences rising demand. As industries expand globally, these components become essential for seamless operations.

7. Transition to High Voltage and High Current Solutions

New innovations in industrial plugs and sockets are revolutionizing the landscape of power distribution for heavy-duty equipment. The shift towards high-voltage and high-current solutions is enhancing reliability and performance across factories, construction sites, and energy projects. These cutting-edge components empower industries to operate more efficiently by providing robust and dependable power connections.

By embracing advancements in plug and socket technology, businesses can optimize their operations, minimize downtime, and ensure seamless productivity. These innovations mark a significant step forward in meeting the growing demands of modern industrial equipment, driving progress and efficiency in various sectors.

Conclusion

The new generation of industrial plugs and sockets represents innovation and development. By prioritizing safety, reliability, and efficiency, they empower industries to achieve greater success. Industrial plug and socket suppliers embrace technological advancements, these critical components continue to shape the future of industrial power connections.

Thanks I have just been looking for information about this subject for a long time and yours is the best Ive discovered till now However what in regards to the bottom line Are you certain in regards to the supply