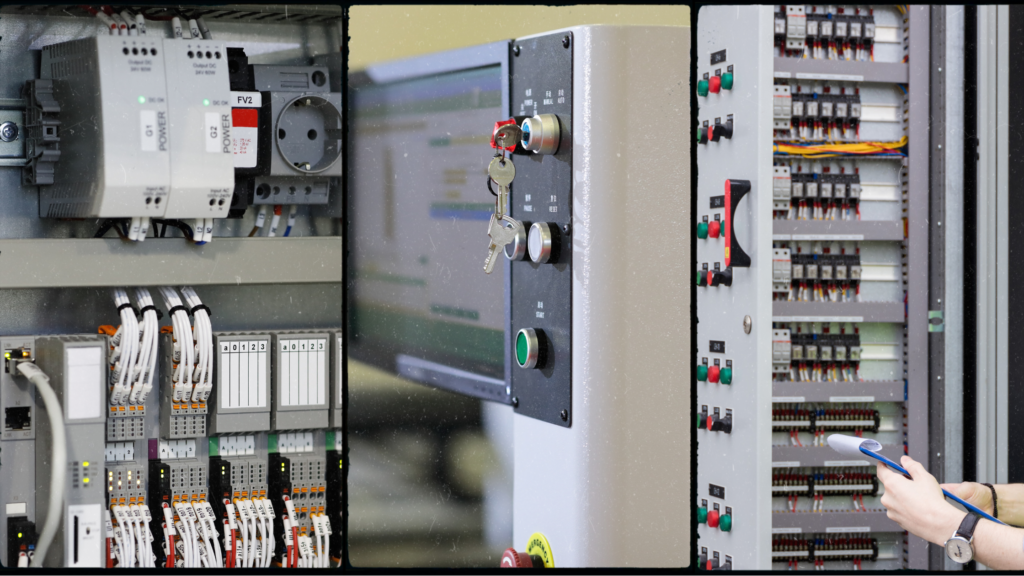

Schneider Electric is a global leader in industrial automation and control solutions. They offer a wide range of products, such as programmable logic controllers (PLCs), variable speed drives, human-machine interfaces (HMIs), and supervisory control and data acquisition (SCADA) systems. These products can help you optimize your operations, improve your efficiency, and reduce your costs.

But how can you integrate Schneider electric automation products with your existing systems and devices? In this blog post, we will share some tips and best practices for successful integration.

1. Identify Your Automation Needs and Objectives

Before you start integrating, you need to have a clear idea of what you want to achieve with automation. What specific processes do you want to automate, and what outcomes are you aiming for? This will help you choose the right Schneider electric automation products and determine how they will fit into your existing ecosystem.

2. Assess Your Existing Systems and Software

You need to understand the architecture, data flow, and dependencies of your current setup. How do different systems interact with each other, and what are the potential bottlenecks or areas for improvement? You also need to ensure data compatibility between your existing systems and the Schneider electric automation products. This might involve data mapping, transformation, or cleaning processes to ensure seamless information exchange.

3. Choose the Right Integration Method

There are different ways to integrate Schneider electric automation products with your existing systems and devices, depending on your needs and preferences. Some of the common integration methods are:

- Point-to-point integration: This is the simplest form of integration, where you connect two sub-systems to support one combined function. For example, you can connect a Schneider electric PLC to an existing device using a communication protocol, such as Modbus or Ethernet.

- Vertical integration: This is where you connect more than two systems to support multiple functions by siloing each function from the bottom up, creating a vertical integration of sub-systems into a larger whole. For example, you can connect a Schneider electric PLC to a Schneider electric HMI, and then to a Schneider electric SCADA system, to create a complete automation solution.

- Star integration: This is where you connect each sub-system to other sub-systems using point-to-point connections, creating a highly interconnected network of sub-systems. For example, you can connect multiple Schneider electric PLCs to each other, and then to a central Schneider electric SCADA system, to monitor and control different processes.

- Horizontal integration: This is where you use one separate sub-system as the interface between all other sub-systems, allowing them to communicate with each other without a direct connection. For example, you can use a Schneider electric SCADA system as the interface between multiple Schneider electric PLCs and other devices, such as sensors, actuators, or cameras.

- Common data format integration: This is where you use a common data format, such as XML or JSON, to enable each sub-system to convert information from its native format to a common format and vice versa. This reduces the number of data transformations needed and simplifies maintenance. For example, you can use a common data format to exchange data between a Schneider electric PLC and a third-party software, such as a cloud service or a business intelligence tool.

4. Test and Troubleshoot

After you have integrated your Schneider electric automation products with your existing systems and devices, you need to test and troubleshoot the integration to ensure that everything works as expected. You can use various tools and techniques, such as simulation, debugging, or logging, to identify and resolve any issues or errors.

5. Monitor and Optimize

Once you have successfully integrated your Schneider electric automation products with your existing systems and devices, you can monitor and optimize the performance and functionality of your automation solution. You can use the Schneider electric SCADA system or other software to collect and analyze data, generate reports, and make informed decisions. You can also use the Schneider electric EcoStruxure platform to access advanced features, such as predictive maintenance, energy management, or cybersecurity.

Conclusion

Integrating Schneider electric automation products with your existing systems and devices can help you achieve your automation goals and improve your operational efficiency. However, integration can also be challenging and complex, requiring careful planning and execution. By following the tips and best practices we shared in this blog post, you can ensure a smooth and successful integration.

If you need more help or guidance on how to integrate Schneider electric automation products with your existing systems and devices, you can contact us. We have a team of experts who can assist you with your integration needs and provide you with the best automation solutions.

Contact us today and get started with your integration project.

I do not even know how I ended up here but I thought this post was great I dont know who you are but definitely youre going to a famous blogger if you arent already Cheers

You consistently deliver high-quality content.

Thankyou Tyree! You should check out our website currently where we bringing to you more valuable Industry Insights.