In industrial automation, proximity sensors are critical for detecting the presence or absence of objects without physical contact. Omron, a global leader in automation and sensing technology, offers a rich and varied portfolio of proximity sensors tailored to diverse applications. In this guide, we’ll dive deep into all the main Omron proximity sensor types, explain how they function, detail their key advantages, and help you choose the right one for your needs.

What Is a Proximity Sensor — and Why Choose Omron?

A proximity sensor detects nearby objects without any physical contact, typically by emitting and sensing some form of field (magnetic, electromagnetic, or capacitive) to identify when something enters its detection range. Omron’s proximity sensors are known for their precision, durability, and wide variety of form factors, making them ideal for manufacturing lines, robotics, process automation, safety systems, and more.

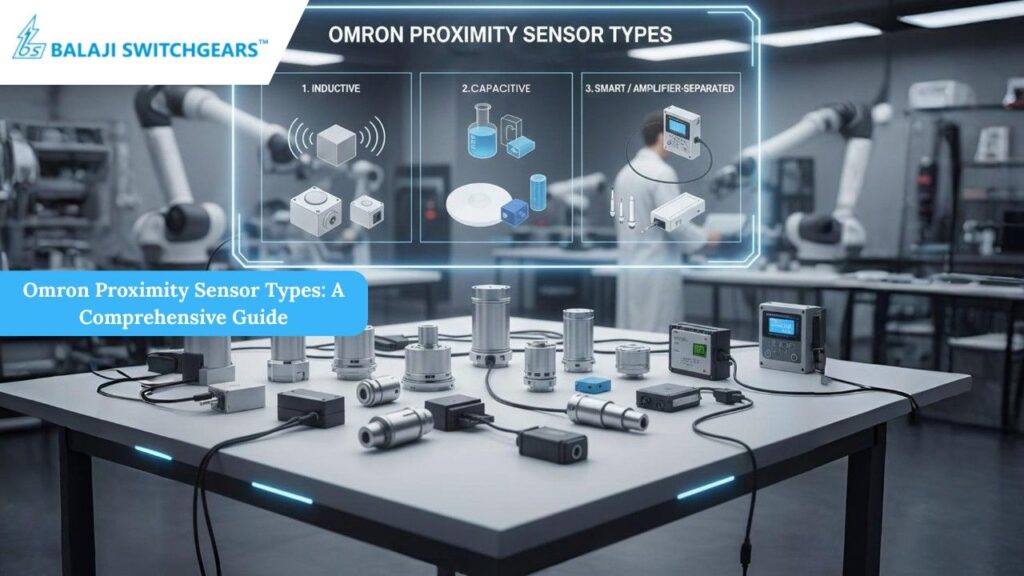

Omron offers different categories of proximity sensors, each optimized for a specific detection method or environment. According to Omron’s industrial-automation website, these include cylindrical, rectangular, separate-amplifier, capacitive, and “other” special-application sensors.

Main Omron Proximity Sensor Types

Here are the key types of Omron proximity sensors, and what makes each of them useful:

1. Inductive (High-Frequency Oscillation) Proximity Sensors

How They Work:

Inductive proximity sensors use a high-frequency oscillating magnetic field. When a metal object (usually ferrous or non-ferrous) enters this field, the sensor detects a change and triggers an output.

Key Sub-Types / Variants:

- Cylindrical Inductive Sensors: These are tubular sensors (e.g., M8, M12, M18 sizes) and are available in shielded and unshielded versions.

- Rectangular / Block Style: These have a block-like housing rather than a round body, making them suitable when space is constrained.

- Separate-Amplifier Inductive Sensors: In these, the sensing head is separate from the amplifier, giving flexibility in mounting and potentially reducing size or heat in tight spaces.

- Long-Distance Inductive Models: For applications that need sensing at a longer range, Omron provides dedicated long-distance variants.

- High-Durability / Spatter-Resistant / Harsh Environment Models: These are designed to resist environmental stress like welding splatter, chemicals or water.

When to Use:

- Detecting metal parts (ferrous or non-ferrous) in assembly or processing lines.

- Environments with contaminants (metal chips, welding spatter) — use the rugged/spatter-resistant versions.

- Tight mounting spaces — cylindrical or slim block types help.

2. Capacitive Proximity Sensors

How They Work:

Capacitive sensors detect changes in capacitance when an object enters the sensor’s electrical field. Unlike inductive sensors, they can detect non-metal objects: plastics, liquids, powders, and more.

Variants:

Omron has capacitive sensors that come in different housing shapes and sizes, and with different sensitivity levels depending on the dielectric constant of the target material.

When to Use:

- Detecting plastics, liquids (water, oil), granules, powders, or any non-metal target.

- Machine processes where both metal and non-metal detection is needed (e.g., packaging machines, chemical processes).

3. Smart / Amplifier-Separated Proximity Sensors

How They Work:

These sensors separate the sensing head (the part that “touches” the field) from the amplifier (which processes the signal). This separation allows users to put the small head in tight or harsh locations, while keeping the amplifier in a safer or more accessible place.

Example Series:

- E2NC Smart Proximity Sensor – Omron’s E2NC series provides a separate amplifier, allowing high-precision sensitivity settings.

- E2E / E2E NEXT – Some versions have advanced features like IO-Link communication and quadruple distance models.

When to Use:

- When installation space is constrained or challenging.

- When you need to adjust sensitivity remotely or fine-tune detection via the amplifier.

- Applications requiring digital integration: e.g., IO-Link versions feed diagnostics data back to a controller.

4. “Others” – Special-Application Proximity Sensors

Omron also provides a range of specialized proximity sensors for niche or demanding use cases. Some notable ones include:

- Ultra-long distance sensors (TL-L): Designed for very long sensing ranges (e.g., 100 mm) for both ferrous and non-ferrous substances.

- Magnetic Proximity Sensors (GLS): Useful for detecting magnets or magnetic targets.

- Long-barrel Inductive Sensors (E2E2): These have extended sensing heads for mounting where clearance is limited.

- All-metal Long-distance Types (E2V-X): Able to detect both aluminum and iron from a distance.

- IO-Link Models: Some special versions support IO-Link in rugged environments — e.g., standard or spatter-resistant IO-Link sensors.

When to Use:

- Automation systems needing long-range detection.

- Environments with welding, spatter or chemical exposure.

- Systems requiring advanced connectivity (IO-Link) and remote diagnostics.

Key Technical Concepts to Understand

To choose the right type of Omron proximity sensor, it helps to know certain technical terms and their implications:

- Sensing Distance (Operating Distance): The maximum distance at which a sensor reliably detects a target. For inductive sensors, this depends on the size of the metal target and its material.

- Shielded vs Unshielded:

- Shielded: The sensing field is more contained. Good when mounting flush with metal.

- Unshielded: Longer sensing reach but more influenced by surrounding metal.

- Shielded: The sensing field is more contained. Good when mounting flush with metal.

- Output Types: Sensors typically offer different electrical outputs: PNP, NPN (sinking / sourcing), 2-wire or 3-wire DC, sometimes AC.

- Electrical Protection / Durability: Many Omron sensors are built for harsh conditions: water, welding spatter, high temperatures.

- Amplifier Options: With separate amplifiers or IO-Link, you can fine-tune sensitivity, get diagnostics, or adjust in real-time.

Choosing the Right Omron Proximity Sensor: Buyer Guidance

Here’s a structured way to choose the correct Omron proximity sensor type for your application:

- Define Your Target Material:

- Is it metal (ferrous or non-ferrous)? → Inductive

- Is it non-metal (plastic, liquid)? → Capacitive

- Is it magnetic (magnet or magnetic target)? → Magnetic proximity type

- Is it metal (ferrous or non-ferrous)? → Inductive

- Check the Environment:

- Is it dusty, wet, or exposed to chemicals or welding spatter? → Use rugged, spatter-resistant, or IP-rated models

- Is mounting space tight or awkward? → Consider separate-amplifier or long-barrel types

- Is it dusty, wet, or exposed to chemicals or welding spatter? → Use rugged, spatter-resistant, or IP-rated models

- Decide on Sensing Distance:

- Short range (a few mm) → Standard cylindrical or block sensors

- Longer range → Long-distance series

- Short range (a few mm) → Standard cylindrical or block sensors

- Electrical and Output Requirements:

- What supply voltage do you have? (e.g., 10–30 V DC)

- What output type do you need? (PNP, NPN, 2-wire, 3-wire)

- Do you require connectivity / diagnostics? → Consider IO-Link versions

- What supply voltage do you have? (e.g., 10–30 V DC)

- Maintenance and Calibration Needs:

- Do you want to adjust sensitivity later? → Use separate amplifier models

- Do you want remote monitoring or I/O-link for fault alerts? → Use IO-Link capable sensors

- Do you want to adjust sensitivity later? → Use separate amplifier models

- Budget & Lifecycle Cost:

- Basic models are usually more affordable but may lack advanced features.

- Decide whether ROI from smart diagnostics, reduced downtime, or replacement cost justifies a more sophisticated sensor.

- Basic models are usually more affordable but may lack advanced features.

Example Omron Proximity Sensors (Product References)

Here are a few representative Omron proximity sensors to illustrate the types and variety:

- Omron Inductive Barrel Proximity Sensor — a standard cylindrical inductive sensor, suitable for detecting metallic parts.

- Omron E2B‑M12KN08‑WP‑C1 2 m Inductive Sensor — M12-size, long-body variant, 2 m cable, NPN output.

- Omron E2S‑W25 5 m Proximity Sensor — designed for applications requiring long cable reach.

- Omron TL‑W1R5MC1 Proximity Sensor — a compact long-barrel or special-form sensor for constrained mounting.

These examples should help you understand real-world models and match them with application requirements.

Practical Applications: Where Each Type Shines

- Manufacturing / Assembly Lines: Inductive cylindrical sensors (M8/M12) are perfect for detecting metal parts on conveyors or robotic arms.

- Packaging / Food Processing: Capacitive proximity sensors can detect plastic bottles, liquids, or granules.

- Welding Stations: Spatter-resistant inductive sensors or long-distance sensors work well in these high-stress environments.

- Robotics / Tight Spaces: Separate-amplifier sensors let you place the head on a robot or tight-mounted component, while keeping the amplifier elsewhere.

- Smart Factories: IO-Link proximity sensors (like E2E NEXT) provide diagnostics, remote parameter setting, and predictive maintenance capabilities.

Tips for Installation & Maintenance

- Mounting: Use mounting sleeves/brackets properly. For cylindrical sensors, get the correct mounting sleeve so that the sensing face is correctly exposed.

- Wiring: Make sure to wire per the sensor’s output type (PNP/NPN) and use clean, shielded cables if needed.

- Alignment: For best performance, target the sensor to the most consistent part of the object to detect (e.g., the same surface / material).

- Adjusting Sensitivity: If using a separate amplifier, fine-tune it based on the actual object during commissioning rather than just relying on datasheet values.

- Diagnostics & Monitoring: If using IO-Link, configure your controller / PLC to read diagnostics (e.g., temperature, signal strength) — this helps detect issues before they cause failure.

- Periodic Testing: Even if non-contact, perform periodic validation (trigger tests) to ensure the sensor is still detecting reliably.

- Cleanliness: In harsh environments (dust, spatter), clean sensor faces periodically to avoid false readings or performance drift.

Conclusion

Omron offers a versatile ecosystem of proximity sensors, each tailored to different use cases and environments. Whether you need to detect metal parts on a fast-moving production line, sense non-metal objects like liquids or plastics, or deploy smart sensors for predictive maintenance, Omron has a proximity sensor type that fits.

Here’s a quick recap:

- Inductive Sensors: Best for detecting metals. Available in cylindrical, rectangular, and long-distance variants.

- Capacitive Sensors: Ideal for plastics, liquids and other non-metal materials.

- Smart / Amplifier-Separated Sensors: Provide flexibility, remote tuning, and advanced diagnostics.

- Special-Application Sensors: Include long-range, IO-Link, magnetic, and rugged models for challenging environments.

By understanding these Omron proximity sensor types, you can make more informed decisions when designing or upgrading your automation systems. Choose based on your target material, environment, sensing distance, and connectivity needs — and always factor in maintenance and diagnostics for long-term performance.